Process

- Home

- Process

We understand that our customers are more and more seeking unique and personalized phone cases. At Funshare, we offer both in-stock and custom phone case manufacturing to meet the needs of wholesalers, retailers, brands and e-commerce companies.

Receive your cases as fast as 3-5 days, we can produce superior quality products in a shorter period of time.

Benefit from 100% factory direct pricing without sacrificing quality, thanks to our extensive supply chain resources.

Partner with Funshare to reduce your purchasing risk and costs with our convenient MOQ as low as 10-20 per model.

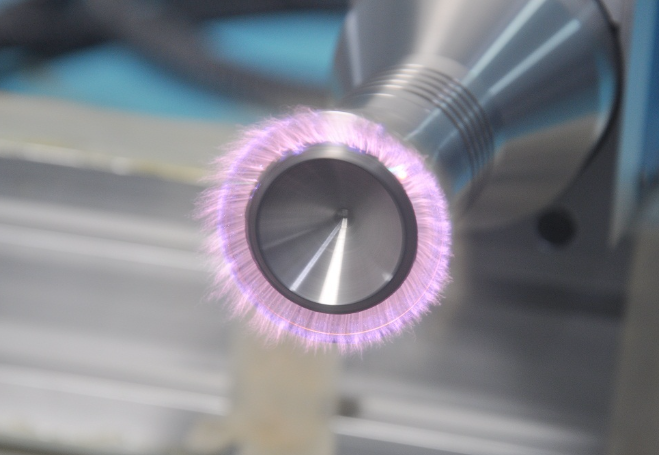

Funshare’s advanced thermos-forming machinery give our leather phone cases increased durability and more comfortable grip.

With over 20 color combinations to choose from, you can create bespoke phone case shades that will impress your customers.

Leave a lasting impression with our assortment of popular printing techniques, including laser engraving to make trendy phone cases.

Copyright © 2023, Funshare. All rights reserved. Powered by MML.