Quality Management

- Home

- Quality Management

We are a reputable phone case company providing excellent quality phone cases for 10 years, having successfully sold our cases to over 10 regions globally.

In the long run, our investment in quality control measures can actually help you reduce maintenance costs while increasing our productivity.

In phone case manufacturing, we have harsh and meticulous steps that can help improve the fintness of materials, buttons and printing of your finshed products.

Select the base case that matches the model and perform a 100% quality check.

Cut off the excess material by machine after ensuring a tight fit to the base case.

Perforate each button with great machine precision.

Exquisite printing on the back side of the case with an advanced laser machine.

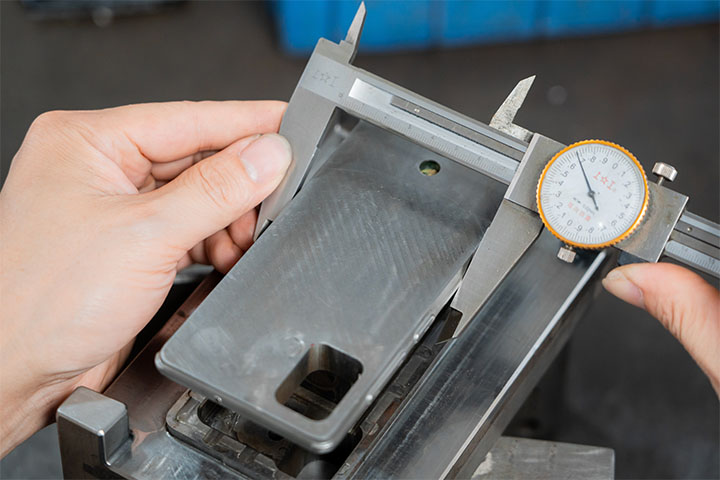

Meticulous mold inspection during the phone case manufacturing process guarantees that each case is to the correct specifications and meets your requirements.

Funshare practices a series of mold inspections, resulting in dependable and captivating phone cases your customers will enjoy and increase your sales.

Placing phone cases in various authentic situations allows us to see potential concerns with the cases and make sure they protect the phone perfectly.

With the help of precision testing equipment, we can simulate any situation phone cases can face for increased durability and protection.

Monitoring and implementing strict in-process quality control ensures that our process complies with industry standards that will strengthen your market hold.

Funshare’s trustworthy IPQC process has brought success to hundreds of customers worldwide, and your brand could be the next.

Running a final quality check before leaving our warehouse gives you the confidence that the phone cases will look and perform as expected.

Never skipping a beat, our inspectors conduct a final round of quality checks, ensuring that every case you receive is in perfect condition.

Copyright © 2023, Funshare. All rights reserved. Powered by MML.